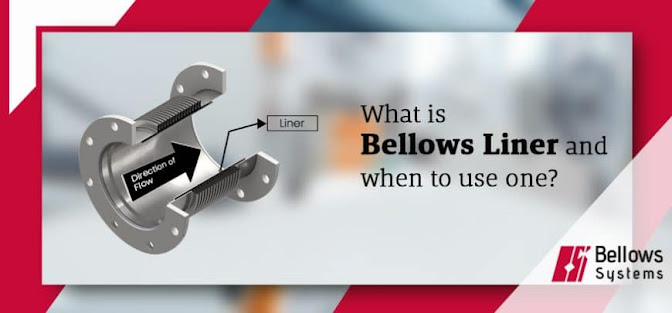

Bellows Liner is an internal sleeve that is used for the following cases,

- To prevent flow induced resonant vibration of bellows due to high flow velocities

- To reduce possibility of erosion from abrasive flow media

- To limit/ minimize the friction losses and create a smooth flow

- To limit/ decrease the surface temperature of the bellows in high temperature applications

Recommendations for proper design and use of a flow liner?

- The liner material should either be same as the bellows material or suitable for the application.

- When sizing a flow liner proper considerations must be given for the flow velocity, liner length and temperature of the flow media.

- When there is possibility for reverse flow, or bi-directional flow use of telescoping liner is recommended.

- When used in applications with abrasive media use thicker liner material to prevent failure in the liner and exposing the thinner bellows material to erosion.

- When lateral deflection or angular rotation is present, the liner should be designed with sufficient radial clearance to prevent interference with ID of the bellows through the entire movement range.

- When bellows are installed vertically in the direction of the flow, proper drain holes shall be provided on the liner to drain fluid from being trapped.

0 Comments